HimachalPradesh-How to prevent and deal with hidden dangers of magnetic generator equipment

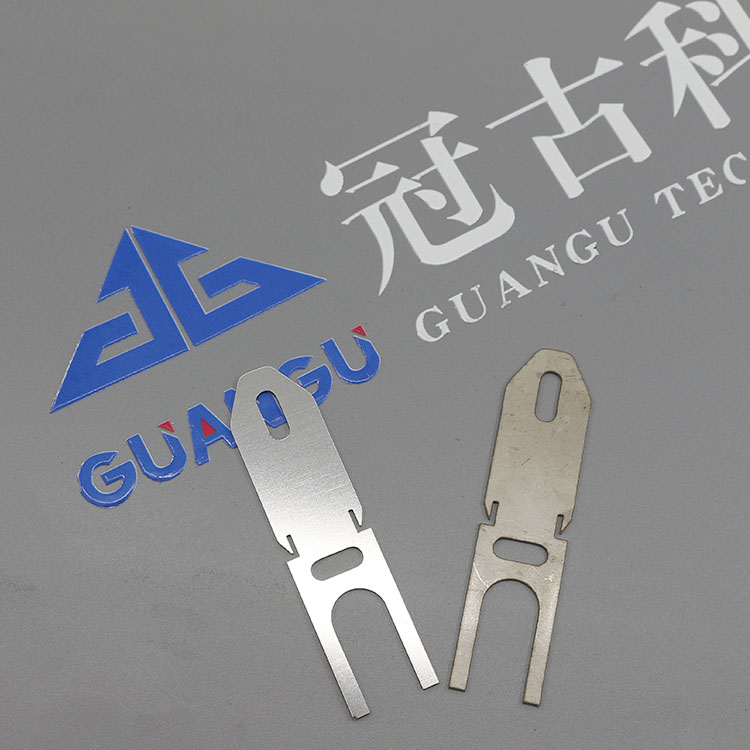

The magnetic deburring machine is mainly composed of base, polishing disc, action table, hydraulic parts, electronic parts, auxiliary parts and so on. Mainly used for various small metal workpieces, wood, furniture, locks, lighting, knives, scissors, clocks, buttons and other tableware, stainless steel tubes, aluminum, iron and other metal furniture tubes, deburring, polishing decorative tubes, but in actual operation , If the operation is not in place, there will be problems. How to deal with it?

In the production process of the magnetic deburring machine, if the operation is improper, it is easy to produce powder sparks. The powder is not a factor, and accidents occur when the density reaches a certain level. The manufacturer of the deburring machine added an environmental dust collector to handle all the dust collection, thereby reducing the sparks generated during the machining process, ensuring the operating environment and the methods of the workers.

There are potential safety hazards prevention and magnetic deburring machine, because it is directly related to the personal life of the employees of the company, so we need to select the appropriate processing technology and equipment before the entire social production and development process to ensure that the equipment is stable in the process of operation. Work and study efficiency.Magnetic polishing machine manufacturers

Wechat

Wechat