HimachalPradesh-Edm machining workpiece refers to various parts and components manufactured by EDM technology, which are widely used in machinery, aviation, aerospace, electronics and other fields, is an indispensable part of modern industry.

Edm technology is a kind of non-contact high-precision machining technology, which uses the high temperature and high pressure effect of EDM discharge to produce tiny melting and gasification on the workpiece surface, and gradually forms the required machining shape through continuous discharge and cooling.

Edm processing workpiece has the following characteristics:

High precision: EDM technology can achieve very high machining precision, can produce small, complex machining shapes.

High surface quality: EDM technology can produce parts with a high surface finish, with surface roughness up to Ra0.1μm.

Difficult-to-process materials: EDM technology can process a variety of difficult-to-process materials, such as hard alloy, ceramics, superalloy, etc.

Flexibility: EDM technology allows parts to be manufactured in a variety of shapes and sizes without the need for custom cutting tools.

No cutting force: EDM technology has no cutting force, will not produce byproducts and deformation.

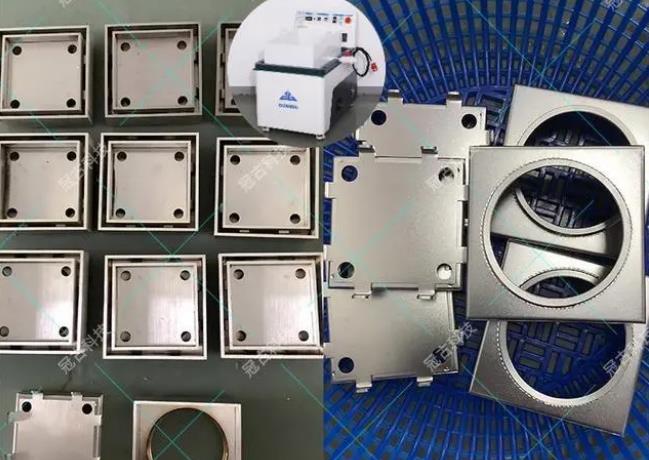

Job polishing

Common EDM processing parts include:

Mold: including plastic mold, casting mold, die casting mold, etc., widely used in various manufacturing industries.

Precision parts: including all kinds of bearings, gears, hydraulic parts, etc., widely used in machinery, automobile, machine tools and other fields.

Complex structure parts: including all kinds of parts in aviation, aerospace, national defense and other fields, with high precision, high strength, high wear resistance and other characteristics.

Edm machining workpiece has the characteristics of high precision, high surface quality, difficult to process materials, flexibility and no cutting force. It is widely used in various fields and provides important support for the development of modern industry.

Magnetic polishing

Edm workpiece polishing method

The polishing of EDM processing workpiece is the process of removing surface defects and oxide layers to achieve a certain surface finish and gloss. The common polishing methods of EDM processing workpiece mainly include the following:

Mechanical polishing: Mechanical polishing is a surface treatment technology based on physical methods. It cuts and abrades the workpiece surface under the action of mechanical forces to achieve the effect of polishing. Mechanical polishing methods can use a variety of equipment, such as grinding machine, polishing machine, vibration polishing machine, etc.

Magnetic polishing method: Magnetic polishing is a surface treatment technology based on the effect of magnetic field. It uses magnetic abrasives in the magnetic field, and uses the friction and impact between abrasives and the workpiece surface to remove the oxidation layer and rust layer on the workpiece surface, so as to achieve the effect of polishing. Magnetic polishing method can be carried out by magnetic polishing machine, which needs to choose magnetic abrasive suitable for workpiece material, and control the magnetic field intensity and polishing time and other parameters.

Magnetic polishing machine

The workpiece polishing method of EDM processing can be selected according to the workpiece material, surface state, polishing requirements and other factors. Common methods include mechanical polishing, chemical polishing, electrochemical polishing and magnetic polishing.

Different polishing methods have their applicable workpiece material, surface state and polishing requirements and other aspects of differences, need to be combined with the actual situation to choose. In the selection of polishing method, we also need to pay attention to the selection of polishing equipment, polishing process control and polishing workpiece cleaning.

Wechat

Wechat